After the near catastrophic emergency landing by a brand new Alaska Airlines B737-9 Max in Portland, Oregon on Friday, the investigation why this happens is ongoing. Some aviation experts now think it may have been a simple pin Boeing forgot to install when it manufactured the aircraft in Seattle.

Every aircraft has several holes in its fuselage. The function of these holes is usually pretty obvious. They are where wires need to pass through on their way from inside to the outside (landing lights, navigation lights, antenna wires, etc.).

They carry the control cables from the pilots’ controls to the control surfaces they command. They make it possible to attach things like the wings to the fuselage, etc.

They accommodate windows through which the passengers can watch the World go by as they travel. And the holes are also the mechanism that allows people to get into and out of an aircraft.

In that role, we call them “Doors.”

Now holes in pressurized vessels have always been a problem for engineers. Holes are always points of weakness and when there is a lot of pressure either outside the vessel (like a submarine) or inside the vessel (like an airplane), you have to spend a lot of time as an engineer making sure your holes don’t open when you don’t want them to and, equally important, that they do open when you need them to.

It’s not an easy task. Nor is it one where you want to cut corners or conduct any “value engineering.”

These are among the hardest tasks in engineering and should be given only to those with vast experience and past success.

More importantly, perhaps, vast experience and a history of learning what doesn’t work from failure. Any door in a pressurized aircraft fuselage is under tremendous stress and force in flight.

A typical cabin differential is eight pounds of force per square inch. What that means is that, in flight, there are eight pounds of force pressing on every square inch of surface, including the doors, trying to blow them out.

The biggest doors in an aircraft are designated “Type A” doors. This is the kind of door that most of us are familiar with as it’s the kind of door we pass through when getting on or off a flight to go visit our grandmother in San Francisco. A Type A door is at least 42 inches wide by 72 inches tall. That’s more than three and a half feet wide and six feet tall. A door that size has an area of 3,024 square inches. At eight pounds per square inch or 3,024 x 8, we get a total force on the door of nearly twenty-five thousand pounds.

Get that? During ordinary flight, each door has to withstand the same load generated on it by cabin pressure as if it were trying to hold back a rocket powered by a Space-X Kestrel engine.

So why aren’t doors being blown off of commercial airplanes all the time? Simple, engineering. Cabin doors are designed to fit into the holes in the fuselage like a wine cork fits into a wine bottle. The doors themselves are larger than the holes they cover. What’s more, they have a wedge shape to them that causes them to seal in the hole more tightly the greater the pressure difference between the outside and the inside.

It’s an elegant solution that ensures that the door cannot be opened in flight. It relies on no complex mechanism other than air pressure to keep it safely closed. On the ground, where there is no difference in air pressure between the outside and the inside, it can be easily opened. Either as a normal course of operation or in an emergency.

The only problem with plug-type doors of this type is that they:

- a. Must open INWARDS

- b. Have to incorporate hinges because they are heavy.

Now that’s the story about regular doors. What about other doors like the doors used for baggage, cargo, and emergency exits?

Usually, they are designed along the same principle – the door in question is made larger than the hole it is intended to cover. But this can cause problems.

For cargo and baggage doors you would like to have a door that opens outwards and then moves up and out of the way. This means a door that is still larger than the hole it plugs but that fits into the hole from the outside, not the inside.

Once you do that, you open up a whole can of – as we say in engineering texts – “whoopass.”

There’s no free lunch. You can’t have a door that opens OUTWARD and a door that is easily, simply, and securely held in its hole by cabin pressure.

So, if you absolutely must have the door open OUT, instead of opening IN, then you are going to have to do a stellar job of engineering to make that door work right.

Meaning works reliably and safely. You cannot cut corners here.

In 1974 a Turkish Air DC-10 crashed outside Paris due to one of its cargo doors blowing out.

The resulting rapid decompression caused the cabin floor in the DC-10 to buckle (the air pressure in the passenger cabin became much higher than the pressure in the cargo section below it).

When the floor buckled, it severed and restricted the control cables running from the pilot’s controls to the control surfaces, rendering the aircraft uncontrollable. Three hundred and forty-six people died as a result.

The cargo doors on the McDonnell Douglas DC-10 were outwardopening, in order to facilitate loading.

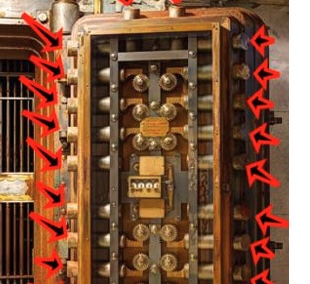

They were kept attached to the fuselage in flight by several “fingers” that rotated outward and then gripped the surface of the inner fuselage. The arrangement was very similar to how many bank vault doors are secured – with heavy, stout pins that bear against the inside of the opening.

Except in the DC-10 the pins were never heavy nor stout (it is an airplane, after all).

The baggage handlers were supposed to close and secure the door by rotating a handle on the outside that forced the pins out and locked the door to the fuselage.

However, the entire mechanism for doing that was rather under-built and under-designed with the result that a strong baggage handler (aren’t they all?) could easily force the lever into position without the pins becoming fully engaged.

McDonnell Douglas was a company known to be intensely interested in the financial aspect of building commercial airliners and not one known to spend more on engineering than could be justified by the resultant return in investment (ROI). MD and Boeing merged in 1996.

Commercial aircraft are required to have a number of emergency exits available for passenger egress.

These exits are normally in addition to the regular cabin doors.

In the past, the emergency exit doors were designed using the same “plug in a hole” principle as the main cabin doors. In other words, the emergency exit doors couldn’t be opened in flight as each had approximately ten thousand pounds of air pressure holding it firmly lodged in its fuselage hole.

This created some problems, however.

The first was that the emergency exit doors were not doors in the first place.

They were just plugs. They had no hinges on which to operate. They simply “stuck” in the hole and, if air pressure allowed (i.e. on the ground) they could be easily pulled out of their holes.

Easily is a relative term.

As I said they still had to hold back ten thousand pounds of force in flight. Which meant they were beefy. And heavy. So the person pulling them out had to be reasonably strong. And they couldn’t be so big that even a strong person couldn’t pull them out. Second, because they fit from the inside, they could only go inside.

Once removed the person who removed them either had to chuck them into the plane, where they could present an obstacle to evacuation. Or had to turn them awkwardly so that they would fit through their hole – and then chuck them outside.

In an emergency, it was deemed that this would be unlikely to be carried out well. So a decision was made to

- a) Make the doors larger

- b) Hinge the doors

This meant that the doors had to open outwards, not inwards. This meant they would have to be actively restrained in their holes by stops and latches, like the DC-10 door, not passively restrained by air pressure as was standard practice.

The simple became complex. It became expensive. This was no job for a junior engineer.

And hopefully, no junior engineer was given the task of designing it.

And hopefully, it wasn’t done on the cheap.

That’s the history.

And, unfortunately, history tells us that practice today is to do it on the cheap. Including the cheapest (i.e. least skilled) labor possible.

Now let us get into the accident.

The required number of emergency exit doors or openings is a function of how many passengers the airline intends to cram into the cabin. Simply, the more passengers the greater the required number of doors. Airplane fuselages are manufactured to accommodate the maximum number of doors.

If some of the emergency exit doors are unnecessary due to low passenger density then the “extra” door openings in the fuselage are covered with so-called “door plugs.”

These plugs attach to the fuselage much as a real door would and are even given provisions such as small vestigial hinges which allow the plugs to be easily “opened” if necessary.

It’s not clear why a decision to make the plugs so easy to open (and remove) vs. simply making them very fast and permanent.

Presumably, this was done to ease certain maintenance tasks as well as to make it easy to convert from a door plug to a real door if desired in the future.

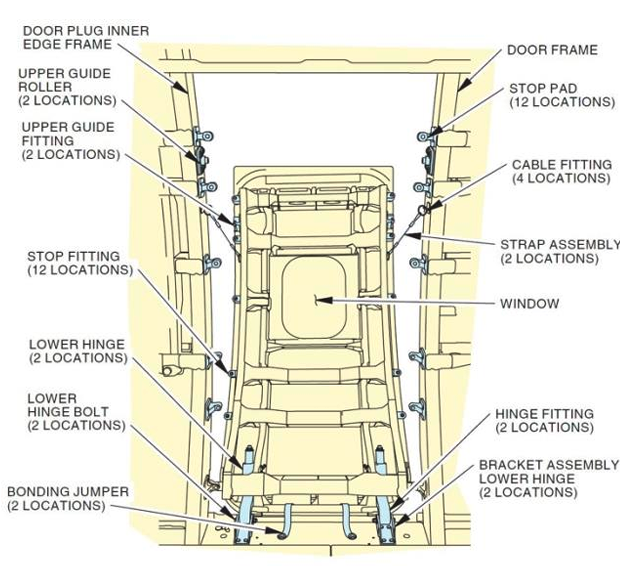

Normally the door plugs are held in the fuselage against 12 “stop pads” which are forged aluminum fittings.

For each stop pad attached to the fuselage, there is a stop pad on the door plug. The door plug stop pads sit INSIDE the door frame stop pads.

This is important. Because the door plug pads are inside the door frame pads, when the cabin is pressurized the pads press against one another. In fact, at full pressurization, there is more than ten thousand pounds on the door plug — equivalent to three Teslas pressing down.

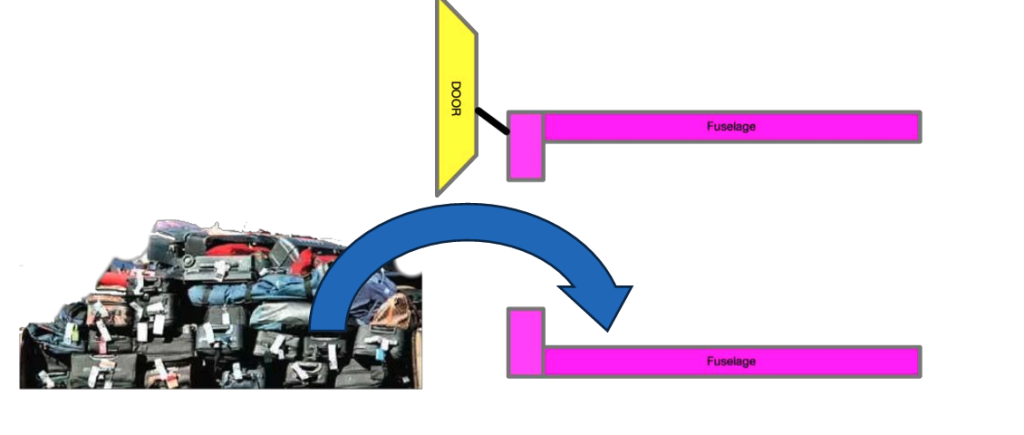

Here you can see how that works. The pink is the outer fuselage of the 737. Yellow are the components of the door plug itself. Specifically the “stops.”

The black cylinders are the centering pins (more on those later) that are used to keep everything aligned. They are essentially dowel pins and have no structural role other than making sure the various pieces remain aligned, particularly when the airplane is not pressurized.

When the airplane is pressurized the pressure differential between the air inside the cabin and the air outside generates a substantial force pushing the stops against one another.

The centering pins depicted as black in the schematic diagram are easy to see as the silver round objects in this picture.

Again, in flight, the pieces are pressed together with substantial force (ten thousand pounds distributed over twelve stops) and the centering pins are not necessary to keep things together.

It’s only when the airplane is unpressurized that the pins help keep things aligned and in place.

Remember that the door plugs are designed to be relatively easy to open and remove if necessary.

Removing the door means simply moving it UPWARDS a bit (“translating” it in engineering speak) so that the stop pads clear one another.

This is facilitated by hinges and guide rollers that exist only to make it relatively easy to open and remove the door plug if desired.

Ordinarily, these hinges and guide rollers would not be used when the aircraft is in commercial service.

Nor are they critical to keeping the door in place during flight. That is what the centering pins are for.

The only use of the door guide rollers and the vestigial hinges at the bottom of the door is during maintenance or when the aircraft is being converted to replace the door plugs with actual doors.

Here is a schematic of how it works (opening and/or removing the door plug) Yellow is the door plug and pink is the fuselage surrounding it. Now that’s great for when you WANT to remove the door…

But not so great when you DON’T want the door to “open.”

How is it supposed to work when you DON’T want to open the door plug? When you want it to stay firmly attached to the airplane even though it needs to resist ten thousand pounds of force trying to blow it outside?

First is the “upper guide roller.”

This is a part of the frame that makes it easy to position the door plug in place.

The door plug is “dropped” into this guide from above, facilitated by the translating (movable up and down) hinges at the bottom.

Note this detail of the “upper guide roller” components. There is a notch at the bottom of the fitting in the door plug.

This allows the guide pin to exit out of the fitting when the door is raised.

And a bolt through the fitting that does not allow that to happen normally.

During assembly, the door plug is closed using small hinges at the bottom (FYI a real exit door in this location is hinged at the top, not the bottom, using a big hinge).

And then dropped onto the roller through the notch. Whereupon the bolt is inserted to secure it.

However, just two small bolts to secure the door plug in the upper guide rollers would not be sufficient.

So each of the door stop pads is also fitted with a kind of bolt — to keep it in place.

I can’t find a name for these fittings so I will simply call them “centering pins.”

For the door plug in the Alaska Air flight to have departed the aircraft it needed to move up before it could move out.

But it should not have been able to move up. The centering pins should have prevented any upward movement.

It should have been stopped by the bolt in the upper guide roller and/or the centering pins.

It was not because on January 6th, 2024 this:

We know that the stop pads themselves were relatively undamaged. They did not fail.

The only way the door plug could have come out is if its stop pads failed (need to find that plug!) OR if it moved up and out.

Given that this design is decades old and has given trouble-free service in those decades, it is unlikely that this is the result of a design error.

The most likely explanation, at this point, is that the centering pins necessary to keep everything aligned failed for some as yet unexplained reason.

Or they were mis-installed at the factory when the plane was built (the plane was a mere ten weeks old at the time of the accident).

Or they were never installed in the first place.

Burning Questions

- A. Given this design is decades old and has never given this kind of trouble, was this a manufacturing defect in this one particular airplane (i.e. missing centering pins)?

- B. Why make the door plug so easy to remove versus a more permanent fuselage attachment?

Gregory Travis is an aviation expert and provided this article.

(eTN): Alaska Airlines B737-MAX 9: Did Boeing Forget to Install a Pin? | re-post license | post content